Piston seals are important components for maintaining the normal operation of mechanical equipment. Wrong choices will lead to media leakage, damage to expensive equipment, and even environmental pollution…

This article will show you the differences between them. Help you to get the best solution according to your application needs.

Table of Contents

ToggleBasic concept analysis

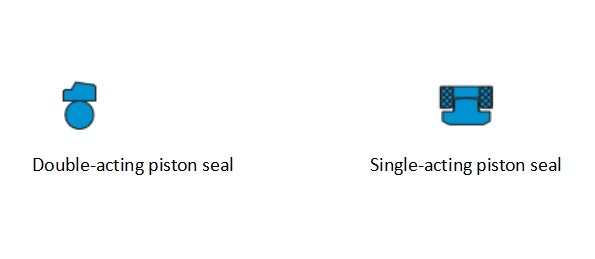

What are double-acting piston seals?

A double-acting piston seal that can seal in both directions and can withstand pressure from both the positive and reverse directions. There is no crack between the piston and the cylinder barrel of the double-acting seal, and the in and out liquids must be sealed through different sealing rings.

Double-acting piston seals are usually used for reciprocating motion, such as in double-acting hydraulic cylinders, construction machinery, forklifts, casting machines, and other equipment.

What are single-acting piston seals?

A single-acting piston seal is that it only acts in one-way sealing. It can only withstand pressure in one direction and seal the pressure in the hydraulic cylinder through the sealing ring.

There is a crack between the piston and the cylinder barrel of the one-way seal, which allows the liquid passing through the piston to flow back to the tank on the other side of the cylinder barrel.

A single-acting piston seal is usually used for one-way hydraulic cylinders and is often used in mechanical equipment such as lifting machinery and hydraulic jacks.

Design and Function

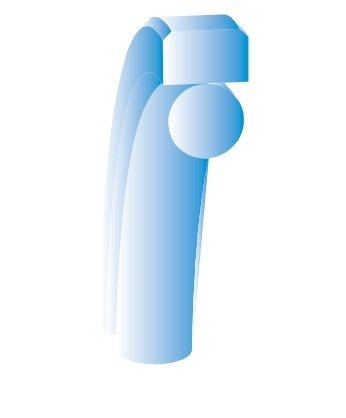

The double-acting piston seal has a symmetrical sealing lip/combined design, and its structure is relatively complex. It can withstand pressure in both directions and is suitable for high pressure. It is generally composed of a PTFE slide ring + O-ring combination.

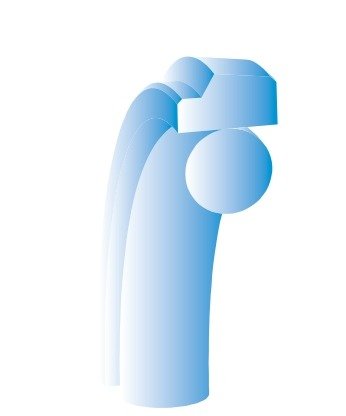

The structural feature of single-acting piston seals is a single-sided sealing lip design, which is relatively simple and only withstands one-way pressure, and is suitable for medium and low pressure.

It is usually required to be matched with a guide ring/retaining ring to prevent seal extrusion.

Advantages

Double-Acting Piston Seal

- Two-way sealing is more reliable

- Symmetrical sealing lip design, consistent two-way pressure bearing capacity (ISO 6020-2 standard test)

- Long service life

- Adaptable to complex working conditions

Single-Acting Piston Seals

- Simple structure, easy installation, and maintenance

- Low manufacturing cost

- Wide range of applications

| Comparison Items | Single-Acting | Double-Acting |

| Pressure direction | One-way only | Two-Way |

| Sealing efficiency | One way higher | Bidirectional balance, higher precision required |

| Installation complexity | Simple (single-side positioning) | Need to be installed symmetrically |

| Cost | Lower (simple structure) | Higher (complex design) |

| Typical Applications | Forklift lifting cylinder, one-way pressure equipment | Engineering machinery cylinders, reciprocating motion systems |

If you still want to know how to choose your application and how to find the right piston seal for you, the TYS team is happy to help you. We are a piston seal manufacturer in China.

We have 25 years of rich experience in the hydraulic seal industry and provide the most cost-effective sealing solutions for customers in China and around the world. Send us your requirements immediately, and let us help your project reach a new level.

Articles you may be interested in:

NBR vs Viton/FKM | Which is More Suitable for Application?

Dynamic Seal vs Static Seal