V-Pack hydraulic seals (also known as V-set seals) are one of the most proven and reliable sealing solutions in modern industrial applications.

Their multi-component structure and self-sealing mechanism allow them to perform efficiently across a wide range of pressures—from low to ultra-high pressure conditions.

Table of Contents

Toggle🔹 Product Structure and Working Principle

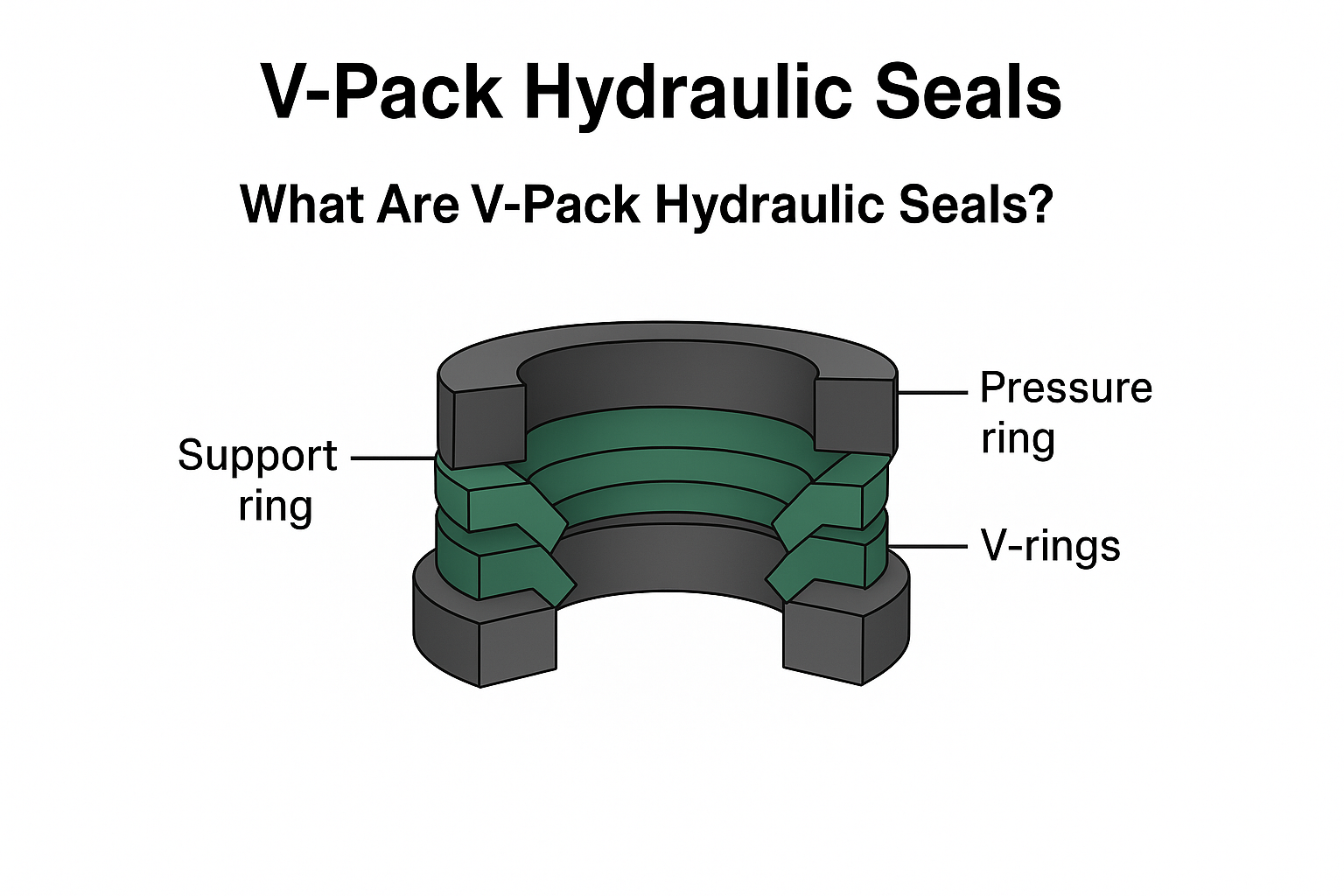

A V-pack seal is a lip-type sealing element with a V-shaped cross-section, composed of three basic components: a support ring, multiple V-rings, and a pressure ring.

-

The support ring features a solid and thick profile to stabilize the seal assembly.

-

The V-rings form the main sealing layers, responding dynamically to system pressure.

-

The pressure ring provides initial compression and ensures close contact with the sealing surface.

Self-Sealing Effect

The unique lip design of the V-ring provides a self-energizing sealing effect.

As system pressure increases, fluid pressure acts on the V-ring lips, forcing them to expand outward and press tightly against the sealing surface.

The higher the pressure, the stronger the sealing performance.

Multi-Stage Pressure Reduction

When several V-rings are stacked together, they form multiple sealing barriers.

The leaked medium must pass through each V-ring sequentially, gradually reducing pressure in each stage.

This design enables the V-pack seal to withstand extremely high pressures — up to 60 MPa or more.

🔹 Design Considerations and Material Selection

Determining the Number of V-Rings

The number of rings in a V-pack seal assembly directly affects both sealing performance and service life.

Generally, 3–5 V-rings strike a good balance between sealing efficiency and friction.

More rings increase sealing capability but also raise frictional resistance and wear.

Therefore, it’s important to consider not only the pressure level but also the movement speed and fluid characteristics when selecting the ring quantity.

Material Types

Material selection is crucial for performance and longevity.

Common materials include rubber, fabric-reinforced rubber, and plastic composites.

| Material | Typical Medium | Temp. Range (°C) | Pressure (MPa) | Key Features |

|---|---|---|---|---|

| NBR (Nitrile Rubber) | Hydraulic oil, water, emulsion | -30~100 | ≤40 | Excellent general-purpose seal |

| FKM (Viton®) | Chemical fluids, high-temp media | -20~200 | ≤40 | Superior heat and chemical resistance |

| Fabric-Reinforced Rubber | Hydraulic oil, water | -30~80 | ≤60 | Excellent anti-extrusion capability |

| PU (Polyurethane) | Hydraulic oil | -30~80 | ≤60 | Outstanding wear resistance |

| PTFE (Polytetrafluoroethylene) | Acids, alkalis, chemicals | -196~260 | ≤100 | Low friction, high extrusion resistance |

Fabric-reinforced rubber is one of the most popular materials for V-rings because the embedded fabric enhances stiffness and prevents extrusion.

PTFE materials, on the other hand, provide unmatched low friction and are ideal for both low- and high-pressure environments.

For more information, refer to our guide: A Comprehensive Guide to PTFE Seals.

The support and pressure rings are usually made from metals, plastics, or phenolic resins.

Soft metals like copper or aluminum alloys are recommended, as they balance rigidity, elasticity, and machinability.

🔹 Advantages and Application Performance

Technical Advantages

V-pack hydraulic seals are among the oldest yet most durable lip-type sealing designs, offering clear benefits:

-

High-Pressure Adaptability: Multi-ring stacking allows for outstanding sealing performance under high pressure.

-

Excellent Misalignment Tolerance: Effectively handles eccentric motion of pistons and rods.

-

Adjustable Compression: When leakage occurs due to wear, the compression can be readjusted to restore sealing performance.

-

Ease of Installation: The split-ring design allows for installation without complete disassembly.

-

Broad Compatibility: Suitable for both static and dynamic applications, even under low-speed rotary motion.

However, users should note a few limitations—relatively high friction and the need for sufficient axial space for installation.

🔹 Typical Applications

Thanks to their robust design and versatility, Vee-pack hydraulic seals are widely used across multiple industrial sectors:

-

Hydraulic and Water Press Machinery:

For reciprocating motion in hydraulic cylinders, rams, and motors, handling pressures above 60 MPa. -

Oilfield Downhole Tools:

Perform reliably under extremely high-temperature and high-pressure conditions. -

Heavy Machinery:

Ideal for harsh working environments where contamination or rough surfaces exist. -

Aerospace & Automotive:

Used in critical systems such as brakes, suspensions, and high-reliability actuators.

🔹 Installation and Maintenance Guidelines

Proper installation is essential for long-term sealing reliability.

Preparation

Ensure that all sealing surfaces meet drawing requirements for size, finish, and chamfer.

The work area must be clean and dust-free.

Lubricate components with compatible oil before assembly.

Installation Steps

-

Lubricate all components evenly.

-

Install the support ring at the bottom of the groove.

-

Install the V-rings with the open lips facing the pressure side—remember the rule: “the lip faces the pressure.”

If multiple rings are used, stagger the cuts at 90° or 180° intervals. -

Install the pressure ring to provide the initial preload.

-

Tighten evenly to achieve the required compression, typically 1.03× the free height.

Maintenance

V-pack seals can be adjusted for wear compensation without replacement.

Minor leakage indicates the need to restore preload via shim, spring, or bolt adjustment methods.

🔹 Troubleshooting Common Issues

| Problem | Possible Cause | Solution |

|---|---|---|

| Excessive Friction | Poor assembly, rough surface | Reinstall properly, improve surface finish |

| Leakage | Wrong direction, insufficient preload, wear | Correct orientation, adjust preload, replace worn rings |

| Seal Damage | Extrusion or incorrect gap | Reduce extrusion clearance, add backup rings |

| Premature Wear | Poor lubrication | Improve lubrication, increase material hardness |

🔹 Conclusion

With continuous advancements in materials and sealing technology, V-pack hydraulic seals remain an indispensable solution in the industrial sealing field.

By optimizing design and material selection, they can handle complex conditions—including high pressure, high temperature, and eccentric motion.

For engineers and maintenance professionals, understanding the working principles and proper installation of V-pack seals will help you maximize system performance and extend seal life.

👉 Contact TYS, a professional hydraulic seal manufacturer in China, for reliable V-pack hydraulic seals and customized sealing solutions for your machinery.

Q1: What is a V-Pack hydraulic seal?

A V-Pack hydraulic seal is a multi-component sealing system made up of a support ring, multiple V-shaped rings, and a pressure ring, offering reliable sealing under high pressure.

Q2: How many V-rings should be used in a V-Pack seal?

Typically, 3 to 5 rings are sufficient to balance sealing performance and friction, depending on system pressure and speed.

Q3: Can V-Pack seals be adjusted after wear?

Yes. The compression can be re-tightened or shimmed to restore the sealing force, extending service life.

Q4: Where can I buy V-Pack hydraulic seals?

You can order directly from TYS, a professional hydraulic seal manufacturer in China, offering OEM and custom designs.