Gasket vs o-ring

Gaskets and O-rings are two common types of seals widely used in fast-moving industries.

Gaskets and O-rings are two common types of seals widely used in fast-moving industries.

he O-ring is a rubber seal with a prototype cross-section.

Nitrile rubber and FKM are both very commonly used sealing materials, as elastomers they have their own unique properties and applications.

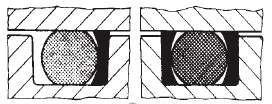

Also known as mechanical face seals or heavy duty seals,it also called Duo cone seal or metal seals.

Vulcanized rubber has all the features that make it ideal for industrial use. As we examine its various uses, it will become increasingly apparent how

Great buildings are built brick by brick. Likewise, our great modern economies are built on the backs of key components and materials that power our

Replacing hydraulic cylinder seals typically involves the following steps:

O-ring seals are widely used, mainly in static seals and dynamic seals. Static seals include box cover seals, bearing outer ring seals, etc., and dynamic

Industry seals are important in machinery to avoid leakage, maintain the pressure level, and keep contaminants out. When done properly, seals not only prolong an

PTFE (its trademark is Teflon) and fluororubber (its trademark is Viton) are commonly used raw seal materials. What is the difference between them? Is PTFE

Lip seals are an important part of modern industries, where they help contain lubricants, keep contaminants at bay, and prevent leakage. This guide will cover

PTFE gaskets play an important role in the industry’s regular operation. This article will help you understand what PTFE seals are and their functions and