What Is PTFE? A Complete Guide for Hydraulic Seal Buyers

If you work with hydraulic cylinders, valves, pumps, or any high-performance sealing systems, you will often hear the term PTFE. But what exactly is PTFE, and why is it so widely used in hydraulic seals?

This guide explains PTFE in a clear, simple way so you can understand what it is, how it works, and why it matters for your applications. As a hydraulic seal manufacturer, we help you learn how PTFE can improve the performance and reliability of your equipment.

Table of Contents

ToggleWhat Is PTFE?

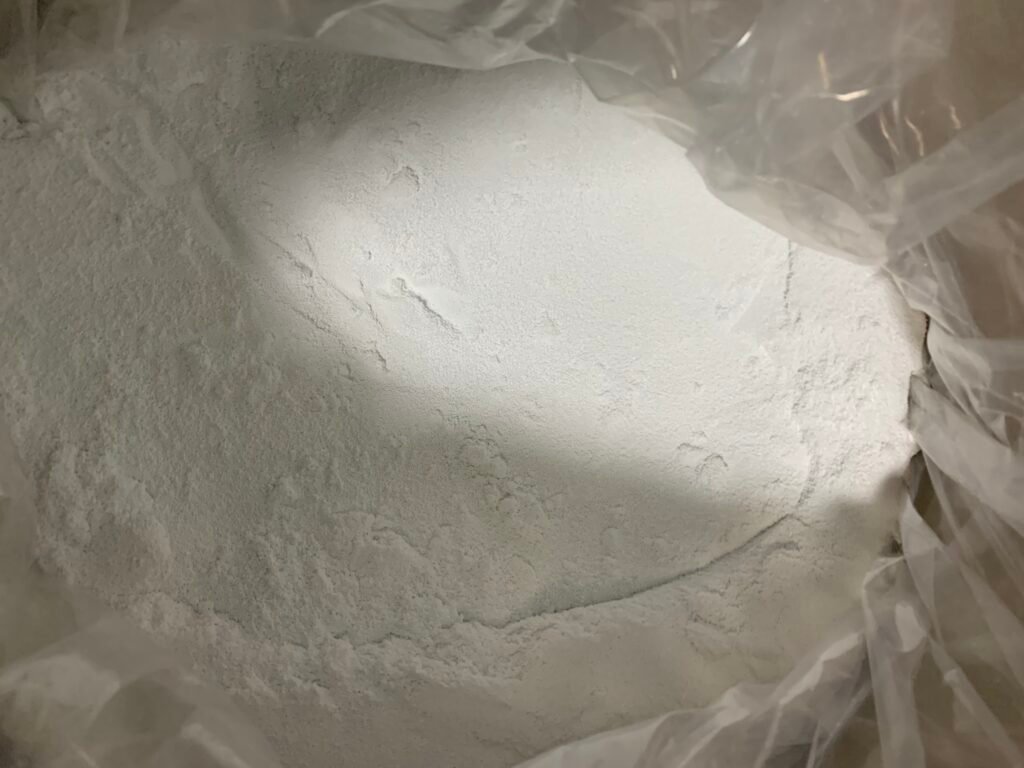

PTFE (Polytetrafluoroethylene) is a high-performance fluoropolymer material made from tetrafluoroethylene.

In everyday industries, PTFE is also known as Teflon, a well-known trademark.

PTFE is one of the most chemically inert and low-friction materials in the world. It can handle extreme temperatures, aggressive chemicals, high pressure, and high-speed motion — which is why it is commonly used in advanced hydraulic seals, rotary seals, O-rings, and other sealing components.

If you need seals that can survive harsh working environments, PTFE is one of the best materials you can choose.

Why PTFE Is Unique—Core Material Features

Below are the key features that make PTFE outstanding for hydraulic sealing systems:

1. Exceptional Chemical Resistance

You can use PTFE in almost any chemical medium, including strong acids, strong alkalis, solvents, oils, and gases.

-

It resists corrosion even under high temperature.

-

It does not react with most chemicals.

-

It is suitable for chemical plants, oil & gas, and high-purity applications.

For hydraulic seals working in aggressive fluids, PTFE ensures long service life and stable sealing.

2. Ultra-Low Friction and Self-Lubrication

PTFE has one of the lowest friction coefficients among all solid materials.

-

Lower friction = less heat, less wear, and longer seal life

-

Ideal for high-speed rotary or reciprocating motions

-

Suitable for dry-running or minimal lubrication conditions

This is why PTFE is widely used in PTFE rotary shaft seals and PTFE guide rings.

3. Outstanding Temperature Resistance

You can rely on PTFE in extreme hot and cold environments:

-

Continuous working temperature: −200°C to +260°C

-

Does not harden, crack, or melt

-

Perfect for high-temperature hydraulic oils and cryogenic systems

This performance makes PTFE a top choice for seals exposed to wide temperature changes.

4. Non-Stick and Easy-Clean Surface

PTFE has a very low surface energy:

-

Dust, oil, and contaminants cannot easily stick to it

-

Excellent for clean, hygienic, or food-grade environments

-

Reduces buildup and helps maintain stable performance

5. Excellent Electrical Insulation

If you work with equipment requiring electrical isolation, PTFE is a reliable insulator with stable dielectric properties.

6. Safe, Non-Toxic, and FDA-Compliant

PTFE is suitable for food processing, medical equipment, and pharmaceutical machinery.

Mechanical Characteristics: What You Should Know

While PTFE has many advantages, its mechanical properties also affect seal design.

Here’s what you should consider:

PTFE Strengths

-

Good tensile strength

-

High elongation and good deformation recovery

-

Great resistance to pressure and extrusion when filled with bronze or carbon

-

Excellent dimensional stability

PTFE Limitations

-

Pure PTFE has lower wear resistance

-

It may creep under long-term load at high temperature

-

It is softer than metals and requires proper backup or support

This is why most PTFE seals in hydraulic cylinders are made using filled PTFE, such as:

-

Bronze-filled PTFE

-

Carbon-filled PTFE

-

Glass-filled PTFE

-

Graphite-filled PTFE

Modified PTFE blends greatly improve wear resistance, pressure resistance, and sealing performance.

Where PTFE Is Used: Practical Applications

PTFE is widely used across many industries, especially in hydraulic and industrial sealing applications.

Hydraulic & Pneumatic Systems

-

PTFE dust seals

-

PTFE perfluoroelastomer sealing rings

Industrial Machinery

-

Injection molding machines

-

Presses

-

Pumps and compressors

Chemical Processing

-

Valves

-

Pump diaphragms

-

Chemical-resistant gaskets

Automotive & New Energy Equipment

-

High-speed rotary seals

-

EV gearbox shaft seals

-

High-temperature lubricant systems

Food & Medical

-

Medical device components

-

Food-grade seals

-

Clean-room equipment

If your equipment requires low friction, high temperature resistance, or chemical stability, PTFE is usually the best option.

Why PTFE Seals Improve Hydraulic System Reliability

Hydraulic systems often face challenges such as:

-

High pressure

-

Abrasive media

-

High-speed reciprocating motion

-

Temperature fluctuations

-

Contamination and chemical attack

PTFE provides superior sealing due to:

-

Lower friction → less heat and wear

-

Better pressure resistance (with filled PTFE)

-

Longer service life

-

More stable operation under extreme conditions

This is why more companies are replacing traditional NBR or PU seals with PTFE-based sealing solutions.

Summary: Is PTFE the Right Material for Your Seals?

If you need hydraulic seals that can survive high speed, high pressure, high temperature, or corrosive media, PTFE is likely the best material for your application.

You should choose PTFE seals when your system requires:

-

Low friction

-

High wear resistance

-

Chemical resistance

-

High temperature tolerance

-

Long service life under harsh conditions

As a professional manufacturer of hydraulic seals, we can help you select the right PTFE grade and structure for your equipment.

TYS PTFE Seals

TYS continues to invest more money and time in the research and development of polytetrafluoroethylene sealing materials. The proprietary modified PTFE material seals developed independently can meet the specific needs of various industries.

TYS continues to provide more efficient, safe, environmentally friendly, and corrosion-resistant sealing materials with broad application prospects. In the future, as technology continues to develop and application needs continue to evolve, the application field of polytetrafluoroethylene sealing materials will become increasingly extensive and more comprehensively developed and applied.

FAQ

Q1: What is PTFE made of?

PTFE is made from polymerized tetrafluoroethylene and belongs to the fluoropolymer family. Its strong carbon-fluorine bonds give it exceptional chemical resistance and stability.

Q2: Is PTFE good for hydraulic seals?

Yes. PTFE is one of the best materials for high-pressure, high-speed, and high-temperature hydraulic systems because of its low friction, chemical resistance, and long service life.

Q3: What temperatures can PTFE withstand?

PTFE can operate continuously from −200°C to +260°C without cracking, melting, or degrading.

Q4: What are the advantages of PTFE over rubber seals?

PTFE offers lower friction, higher temperature resistance, better chemical compatibility, and a much longer lifespan compared to traditional rubber materials such as NBR or PU.