Sealing technology is a crucial component of engineering, and various types of seals play an indispensable role in numerous mechanical equipment and engineering projects.

Static seals, as the most fundamental type of seal, have their principles and classifications crucial to understanding sealing technology. This article will help you understand the concept of static seals, providing a comprehensive overview of this topic.

Table of Contents

ToggleWhat is meant by static seals?

Static seals are a method of sealing a surface without moving. Compared to dynamic seals, static seals are simpler and more reliable and are widely used in various mechanical equipment.

In a static seal, a certain sealing gap is formed between the seal and the sealing surface, achieving the sealing effect through static pressure or surface tension. Static seals are typically used for sealing parts that are stationary or move at low speeds, such as O-rings and gaskets.

Static Seals types

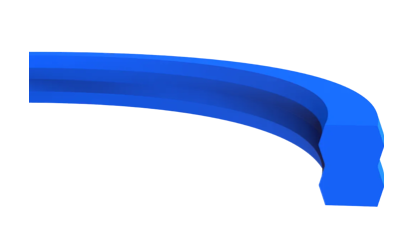

Static seals can be categorized into different types based on the shape and material of the seal, with the most common types being O-rings, flange seals, and head seals (twin-lip static seal designed).

Flat gaskets are suitable for static sealing, while convex and concave gaskets are suitable for sealing surfaces with irregular shapes.

Static seals can also be categorized into metal seals and non-metal seals based on the seal material. TYS is a leading manufacturer of hydraulic seals in China. We manufacture and supply a wide range of static seals, including flange seals 、 head seals, and backup rings.

With 25 years of experience in sealing technology, we can quickly provide high-quality static seals at competitive prices. If you are looking for static seals, contact the TYS team for a quick, free quote.

Advantages and Limitations of Static Seals

Features of Static Seals

1. Excellent Sealing Effect

Static seals offer excellent sealing performance, effectively preventing leakage of liquids, gases, and other media. This is because the seals, when stationary, are able to better maintain contact between the sealing surfaces, resulting in a more effective seal.

2. High Reliability

Because static seals do not require movement, they have a longer service life and a lower failure rate than dynamic seals. Static seals are relatively simple and less prone to failure, ensuring more reliable operation of equipment.

3. Wide Range of Applications

Static seals have a wide range of applications and are suitable for a variety of mechanical equipment, such as pumps, valves, and compressors. They are also highly adaptable to both liquid and gaseous media.

4. Easy Installation

Compared to dynamic seals, static seals are simpler and more convenient to install. This is because static seals do not require the seal to move; installation requires only placing the seal on the sealing surface.

Limitations of Static Seals

1. They cannot provide dynamic sealing and are only suitable for sealing stationary parts;

2. They are susceptible to changes in external pressure, which may cause loosening or leakage;

3. They have relatively low durability and require frequent material replacement.

In summary, static seals offer many advantages, including excellent sealing performance, high reliability, wide applicability, and easy installation. Static seals are widely used in various mechanical equipment.