In the arena of industrial automation, hydraulic seals and pneumatic seals jointly undertake key tasks such as driving, lifting, and clamping. Their core working principles seem similar—both prevent fluids from leaking to the outside in a closed cavity, thereby maintaining the pressure in the system.

In fact, they are essentially different. Let’s take a look at the differences between them.

Table of Contents

ToggleWorking medium

Hydraulic seals mainly seal liquid media, such as hydraulic oil, water, etc., to prevent external and internal leakage of hydraulic oil. This is the source of the power of the hydraulic system. The molecular structure of the liquid is dense and almost incompressible.

The hydraulic system can easily generate extremely high pressure (usually >20 MPa). Under the same cylinder diameter, its output force is often 5 to 10 times that of the pneumatic system! Hydraulic seals squeeze hydraulic seals through liquid flow to achieve a sealing effect.

Pneumatic seals mainly seal gas media, such as air and other gases, to prevent gas leakage. There are huge gaps between air molecules, which have significant compressibility. When the gas enters the cavity, the pneumatic seal is squeezed to play a sealing role.

The difference in sealing media is the most core and basic difference between hydraulic and pneumatic systems.

Application

Hydraulic seals are suitable for high-pressure, low-speed, high-temperature, and humid conditions, such as hydraulic cylinders, hydraulic pumps, water conservancy projects, etc.

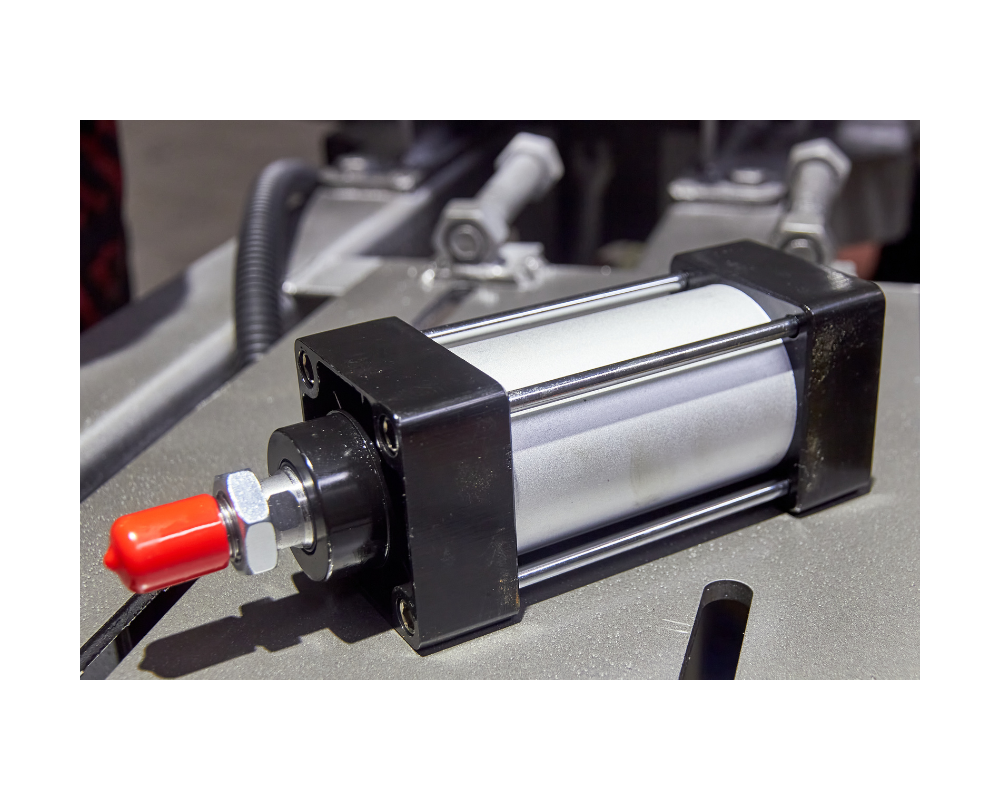

Pneumatic seals are usually used in low-pressure, high-speed, medium-temperature, and dry conditions, such as air compressors, pneumatic cylinders, vacuum equipment, etc.

Performance

Hydraulic seals have the advantages of good sealing performance, suitability for high-pressure occasions, and the ability to withstand high temperature and humidity, but they have disadvantages such as high friction, easy damage, and difficult maintenance.

Pneumatic seals have the advantages of good sealing, low friction, long life, and easy maintenance, but are greatly affected by environmental factors such as temperature and humidity, and are not suitable for high-pressure occasions.

If you need hydraulic seals, you can contact the TYS team to get a free quote or sample. TYS is a professional hydraulic seal manufacturer, providing a full range of hydraulic seals in a wide range of sizes, including piston seals, rod seals, dust seals, guide rings, etc. Factory-direct products are durable and reliable.

Summary

Hydraulic seals and pneumatic seals have great differences in working methods, application scenarios, and materials. When choosing a seal, it is necessary to choose according to specific working conditions and requirements to ensure performance and the best effect.