Today, an old friend suddenly asked me why two seals are used for piston rod seals. Isn’t one seal enough?

Although it seems like a simple question, I was momentarily at a loss for words. A convincing answer couldn’t come to mind. I’ll share a summary with you:

In the hydraulic industry, most working conditions are heavy-duty, making it difficult for a single seal to ensure good sealing performance and the desired long service life.

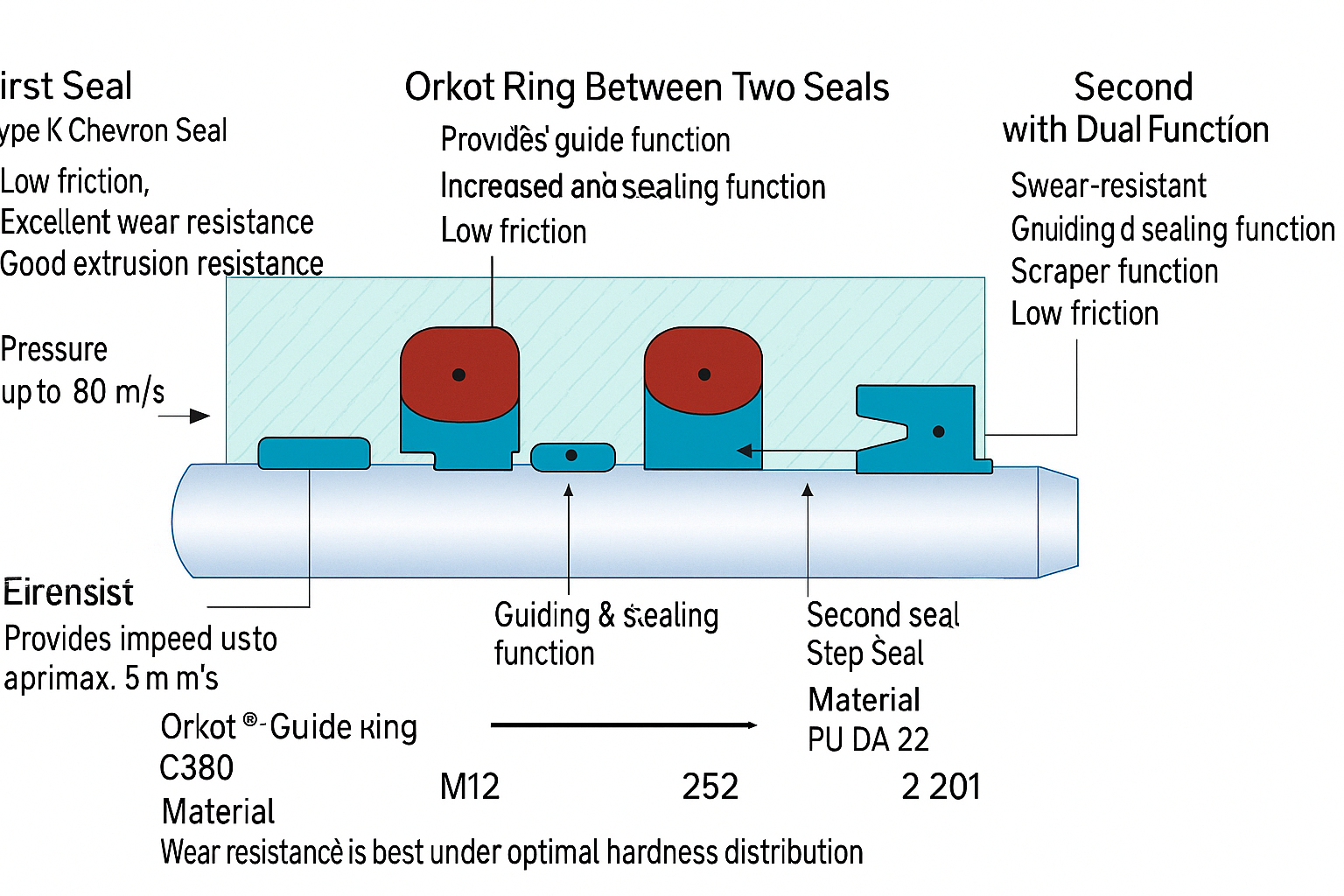

Trelleborg seals are considered an integrated sealing solution, which they call a “tandem sealing system.”

In this “tandem sealing system,” each seal has a specific function, and each seal complements the others.

Table of Contents

ToggleFirst Seal

The first seal is made of PTFE material, which generates low friction and offers excellent wear and extrusion resistance under extreme operating conditions. It allows a thin film of lubricant to pass through the first seal, ensuring the necessary lubrication for the second seal, thereby extending its service life.

Secondary Seal

A tandem seal arrangement requires the primary seal to possess excellent pump back-sucking capabilities. If a double-acting wiper is installed, the secondary seal must also possess this capability. In a system, the interplay of different sealing materials, such as TYS’s proprietary modified PTFE and PU(polyurethane) U cup seals, can ensure enhanced sealing performance.

Guide Ring

Guide rings have two functions: first, to enhance guidance and prevent metal-to-metal friction, and second, to increase oil reservoir space.

Buffer Seals

Commonly made of PU and PTFE materials, HBY buffer seals and step seal buffer seals are common. Step seals can be used as both piston rod seals and buffer seals.

Wiper Seals

Wiper seals are commonly made of a special polyurethane and iron shell or PTFE material; they offer excellent elasticity, dust scraping, and sealing performance, and are wear-resistant.

In summary, using two seals can improve sealing performance and extend service life.