When you start looking for a hydraulic seal manufacturer, you probably want to find a partner who can truly provide value, with reliable manufacturing capabilities and professional hydraulic system knowledge. Then you’ve come to the right place.

TYS is a professional hydraulic seal manufacturer. At TYS, we not only provide reliable hydraulic seals, but we also act as a supplier who communicates with you like an old friend, ready to solve your problems whenever you need us. At TYS, you can obtain consistent dimensions and product quality, flexible custom hydraulic seal services, and competitive pricing.

As a manufacturer focused on hydraulic seals, you’ll notice that we base our materials on helping you find a more reliable solution for your application.

We offer a wide range of materials to meet your different working conditions. All materials used in our hydraulic seals are strictly validated to maintain stable performance.

These materials include PTFE, PU, NBR, FKM, phenolic fabric, POM, PA, and PEEK. These may appear simple to you, but in sealing applications, they represent different levels of wear resistance, temperature tolerance, and media compatibility.

The same material can exhibit completely different characteristics depending on its design, and choosing the right geometry for the right environment often determines whether your system can operate reliably.

Starting from your actual working conditions, we offer flexible and diverse seal designs to ensure the sealing structure perfectly matches your specific pressure, speed, clearance, and media requirements.

When you work with TYS, you receive more than just a seal—you get a complete design solution that truly understands your application needs. We offer a wide selection of designs, including glyd ring seals, step seals, hydraulic U-cup seals, V-packing, hydraulic lip seals, and various combination seal structures.

When time is tight, budgets often increase. Choosing TYS gives you a clear process and stable production, helping you complete the entire process from documentation to delivery more efficiently at a competitive price.

Seal leaks are far more than simple leaks. They can cause downtime and headaches in explaining the process.

Every TYS hydraulic seal undergoes rigorous dimensional and appearance verification before delivery to you, including high-performance stability verification under high-temperature and high-pressure conditions. This consistency protects your reputation.

Sometimes you only have a drawing, sometimes you only have a question.

TYS begins with the actual operating conditions of your equipment and then adjusts materials, designs, and OEM details to meet your specific needs.

Densitometer: Measures the density of the product and the stability of raw materials (error ± 5%), one of the factors.

Durometer: measures product hardness, including:

Shore A: elastomer hardness measurement unit;

Shore D: high hardness elastomer hardness measurement unit; Rockwell hardness: engineering plastics and metal hardness measurement standards.

As elastomer seals, the higher the hardness of the anti-high-pressure performance, the better, but the resistance to low-pressure leakage performance of the lower hardness of the product is poor, hardness of the low-pressure leakage of the anti-pressure performance, but the anti-high-pressure performance is poor.

At the same time, also look at the grooved finish; a low finish requires low product hardness in order to have better sealing performance; the higher the finish, the better the anti-leakage, and the better the sealing performance.

Moisture meter:

Used for production process control, as moisture has a significant impact on the performance of thermoplastic elastomer materials, so we need to keep the humidity in the normal parameters below.

Microscope:

to observe the uniformity of the filling of mixed materials to ensure the stability of product performance.

Microcard Softening Temperature Meter: Measure the maximum temperature of softening and heat distortion (for thermoplastic materials).

Sliding Friction Tester: Measure the abrasion amount and friction coefficient of the material (surface sliding coefficient). The lower the friction amount and coefficient of friction, the more abrasion-resistant the material is, and at the same time, it can reduce the friction resistance and friction heat generation.

Sulfur tester:

Constant temperature oven:

heat aging test (various materials can be tested).

Oil resistance tester: measures the degree of oil resistance (to see the chemical resistance of the material).

Constant temperature and humidity test chamber: simulate high and low-temperature environments to test the sealing performance and life of seals.

Tensile strength tester: test tensile strength, elongation compressive strength, and other mechanical properties of materials.

At TYS, you benefit from flexible manufacturing options tailored to your material selection and production process.

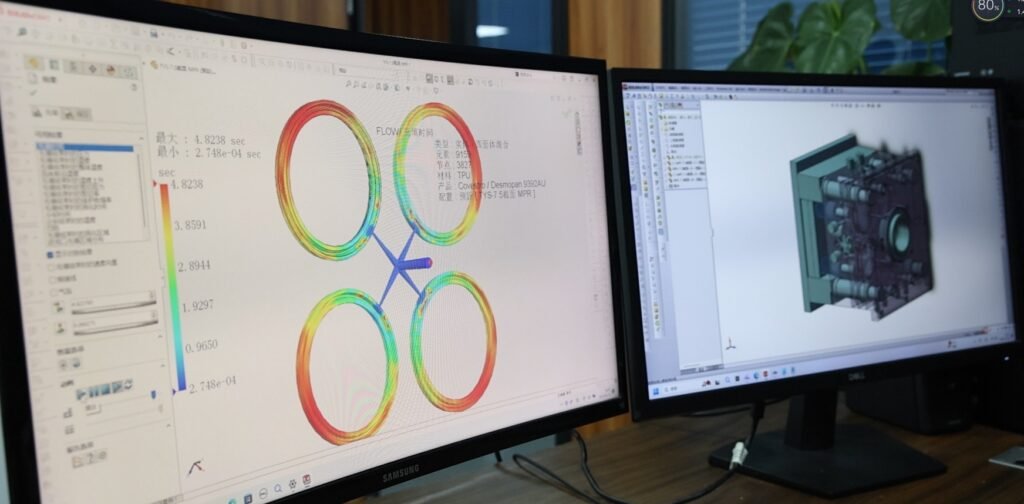

We utilize multiple proven processes, including CNC machining, injection molding, compression molding, sintering, transfer molding, and post-processing. Our engineers can design and manufacture various structures to suit your application and enhance your project.

You may know that different manufacturing processes directly affect dimensional accuracy, consistency, surface finish, and production cost.

For example, our in-house CNC machining process, developed through years of experience, delivers higher dimensional precision, better stability, and a superior appearance, which makes it with high-performance and custom hydraulic seals.

By according to your application conditions, performance requirements, and cost targets, we provide the most suitable manufacturing approach for you.

When you find a truly reliable hydraulic seal supplier, you need not just a product catalog; you need a partner who understands your deepest needs. Choosing a hydraulic seal factory that is technically proficient, capable of consistent delivery, and willing to cooperate with you long-term will give you peace of mind in your procurement and make your equipment operation more reliable.

We offer a full range of hydraulic seals, all manufactured in-house and tested in our comprehensive internal laboratories. From raw material performance testing to durability testing simulating real-world hydraulic cylinder operation, we implement rigorous quality management controls to ensure that we provide high-quality, high-performance hydraulic seals.