Temperature is the ultimate silent commander of your hydraulic systems. It changes material physics and fluid behavior instantly. You must master these thermal effects to prevent costly leaks and downtime. This guide explains how heat and cold transform your hydraulic seals and your system’s reliability.

Table of Contents

ToggleThe Invisible Battle Of Thermal Physics

Think of your hydraulic seal as a professional athlete.

It performs best within a specific “comfort zone.”

When the temperature swings, the seal’s personality changes.

You are no longer managing rubber; you are managing physics.

Temperature affects the elasticity and shape of every seal.

It also changes how the seal interacts with oil.

If you ignore temperature, you invite system failure.

Let’s look at what happens when things get too hot.

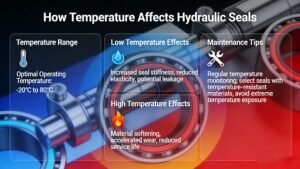

High Temperature: The Great Molecular Softener

When heat rises, your seal becomes softer.

This might sound like a good thing initially.

However, softness reduces the seal’s structural integrity.

It can no longer resist high operating pressures.

The polymer chains start to slide more easily.

This leads to a loss of mechanical strength.

You will notice the seal losing its grip.

Fluid begins to bypass the sealing lip easily.

The Danger Of Material Extrusion

Heat makes your seal material more “fluid-like.”

Under pressure, the soft material enters small gaps.

This process is known as “extrusion.”

It is like pushing dough through a needle.

The edges of the seal get nibbled away.

This creates a “ragged” edge on the seal.

Once extrusion starts, the seal is doomed.

You must ensure the material stays firm.

Understanding Compression Set In Heat

Heat causes a permanent change in seal shape.

This is called Compression Set.

The seal “forgets” how to spring back up.

It stays flattened in its installation groove.

When your system cools, a gap appears.

The seal is now too small for its home.

You will see leaks during the next startup.

High-temperature materials resist this permanent flattening.

Heat Aging And The Brittle Reality

Long-term exposure to heat causes “Heat Aging.”

Chemical bonds inside the rubber start to cross-link.

This makes the seal hard and very brittle.

You might see cracks forming on the surface.

A hard seal cannot follow rod vibrations.

It acts like a piece of dry plastic.

The seal will snap under any sudden load.

You are fighting against irreversible chemical decay.

The Rule Of Ten Degrees

In chemistry, there is a famous observation.

Every 10°C increase doubles the reaction rate.

This applies to seal degradation and oxidation.

A small temperature rise cuts life in half.

You must monitor your system’s peak heat.

Even temporary spikes cause permanent internal damage.

Do not ignore a “warm” hydraulic tank.

It is a sign of dying seals.

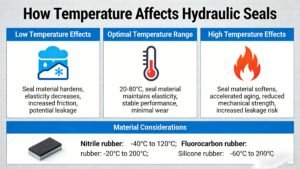

Comparison Of Seal Materials By Temperature

The table below shows the common operating ranges for your industry. Use this to select your “Insurance Policy” against failure.

| Material Type | Low Temp (°C) | High Temp (°C) | Primary Strength |

| Nitrile (NBR) | -30°C | 100°C | Cost-effective, oil resistance |

| Viton (FKM) | -20°C | 200°C | High heat and chemical resistance |

| PTFE (Teflon) | -200°C | 250°C | Lowest friction, extreme range |

| Silicone (VMQ) | -60°C | 225°C | Best for extreme cold environments |

| Polyurethane (PU) | -40°C | 90°C | Extreme wear and tear resistance |

| EPDM | -50°C | 150°C | Good for water and steam systems |

Chemical Warfare At High Temperatures

Heat makes hydraulic fluid much more aggressive.

The chemicals in the oil attack the polymer.

This leads to severe swelling or shrinkage.

Neither outcome is good for your system.

A swollen seal creates massive internal friction.

A shrunken seal leaves a wide leak path.

You must verify fluid compatibility at high heat.

Heat turns a friendly fluid into an enemy.

Low Temperature: The Glass Transition Trap

Cold temperatures turn flexible rubber into glass.

This is the “Glass Transition Temperature” ($T_g$).

Below this point, the seal loses all elasticity.

It becomes a rigid, unmoving ring of plastic.

If the rod moves, the seal cracks.

It cannot deform to maintain the seal.

You will experience immediate, catastrophic fluid loss.

Always check the “Low Temp” rating carefully.

The Problem Of Thermal Contraction

Seal materials shrink much faster than steel.

In the cold, your seal physically gets smaller.

The “squeeze” against the rod is lost entirely.

You are left with a literal hole.

This is why systems leak in winter mornings.

The metal groove stays large, but rubber shrinks.

You need materials that stay “rubbery” in cold.

Look for low-temperature Nitrile or Silicone options.

The Impact Of Cold Fluid Viscosity

Cold oil becomes thick like heavy molasses.

This creates high pressure behind the seal lip.

The seal must work harder to move.

This creates “stick-slip” motion during your startup.

Stick-slip causes the seal to jump and vibrate.

This “chatter” wears down the sealing surface fast.

It can even tear the seal lip away.

You must warm the oil before full operation.

Dry Running During Cold Startups

Thick, cold oil does not flow easily.

It may not reach the seal lip quickly.

Your seal runs “dry” for several seconds.

Friction heat spikes instantly at the contact point.

This localized heat creates “thermal shock” damage.

The seal face burns while the body stays cold.

This leads to surface micro-cracking and failure.

You need a seal with good lubrication retention.

Thermal Expansion: The Tight Groove Crisis

When temperatures go up, seals expand significantly.

Rubber expands much more than the metal housing.

If your groove is too small, problems arise.

The seal will be “crushed” by its own expansion.

The physics can be described simply:

Where $\alpha$ is the coefficient of thermal expansion.

Rubber’s $\alpha$ is much higher than steel’s.

You must design grooves with Thermal Expansion in mind.

Give your seal some “breathing room” in heat.

A 100% filled groove is a death sentence.

It leads to internal material collapse very quickly.

The Friction-Heat Feedback Loop

Friction creates heat; heat creates more friction.

This is a dangerous cycle for your system.

A hot seal expands and presses harder.

This increased pressure generates even more friction heat.

Eventually, the material reaches its melting point.

The seal surface literally “chars” and turns black.

You must use low-friction coatings to break this.

PTFE (Teflon) is excellent for reducing this heat.

The Importance Of Surface Finish And Heat

A rough rod surface creates more friction heat.

A perfectly polished surface can also be bad.

It prevents a protective oil film from forming.

Without oil, the seal burns against the metal.

You need a “balanced” surface for heat management.

This allows a tiny layer of oil to cool.

The oil acts as a heat-transfer medium.

It carries heat away from the seal lip.

Monitoring The “Lip Temperature” Specifically

The oil tank temperature is not the seal temperature.

The seal lip is always hotter than the fluid.

Friction adds 10°C to 30°C at the contact point.

You must factor this “hidden heat” into designs.

If your oil is at 90°C, your seal is at 110°C.

Many materials fail at this specific invisible threshold.

Always leave a “safety margin” in your specs.

Don’t push your seals to their absolute limit.

Environmental Factors Beyond The Fluid

External heat also impacts your hydraulic seals.

Proximity to engines or furnaces adds thermal load.

Sunlight and UV rays can also heat the rod.

This heat travels directly into the seal lip.

You might need heat shields for exposed cylinders.

Consider the “ambient” temperature, not just the oil.

A seal in a desert works harder than indoors.

Always account for the total thermal environment.

Diagnosing Temperature Failures In The Field

You should “read” your seals like a book.

They tell the story of your system’s health.

Look at the color and the texture closely:

-

Square edges: Usually a sign of compression set.

-

Ragged edges: This indicates heat-induced material extrusion.

-

Hard surface: A clear symptom of heat aging.

-

Radial cracks: This points to low-temperature brittle failure.

The failed seal is your best technical teacher.

Do not throw it away without an inspection.

Analyze the failure to prevent the next one.

This is how you build a reliable machine.

The Cost Of Choosing The Wrong Seal

A cheap seal saves you five dollars today.

A thermal failure costs you five thousand tomorrow.

You must explain this logic to your procurement.

Performance in extreme temperatures is an insurance policy.

Invest in high-quality materials like FKM or PTFE.

They handle the “thermal stress” of modern machinery.

They keep your oil inside and dirt outside.

Good seals are the foundation of your uptime.

Strategic Cooling: Protect Your Investment

If you cannot change the seal, change the heat.

Improve your system’s cooling capacity with better heat exchangers.

Check for clogged filters that increase pump strain.

Less strain means less heat and longer seal life.

You are the doctor for your hydraulic system.

Temperature is the fever you must break.

Keep the “body” cool to keep the seals happy.

Your reward is a machine that never quits.

Conclusion

Temperature is the master of seal life and death.

You must balance material properties against thermal reality.

Heat softens and ages; cold hardens and cracks.

Choose the right material to ensure system longevity.

Protect your seals today for a leak-free tomorrow.