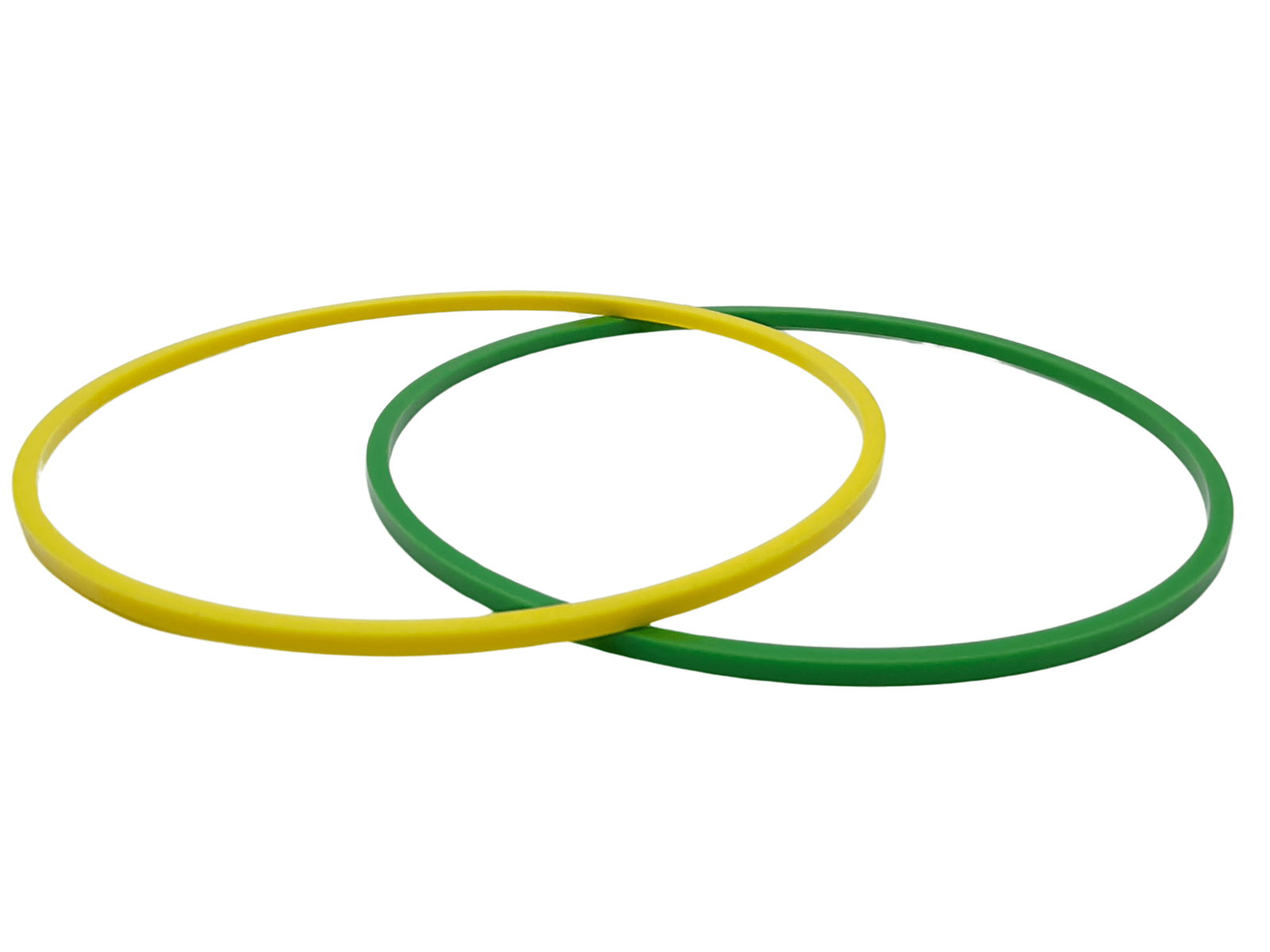

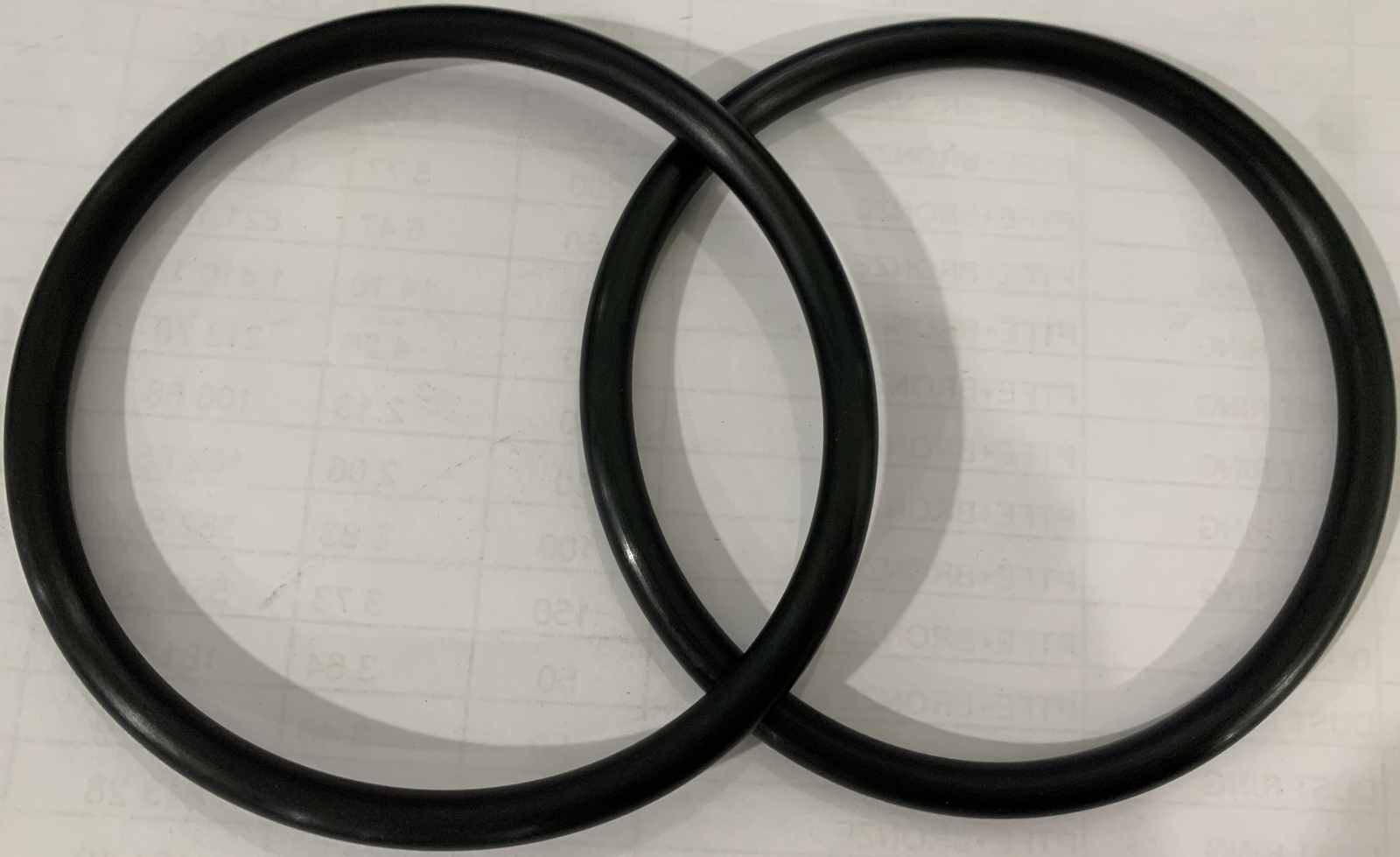

POM Guide Rings VS Phenolic Fabric Resin Guide Rings

Why do some buyers choose POM guide rings while others choose phenolic fabric resin guide rings? The following comparison will help you choose the right

Why do some buyers choose POM guide rings while others choose phenolic fabric resin guide rings? The following comparison will help you choose the right

Phenolic fabric resin guide rings, as high-performance industrial seals, play an important role in modern industry. Their unique physical and chemical properties enable them to

Sealing technology is a crucial component of engineering, and various types of seals play an indispensable role in numerous mechanical equipment and engineering projects. Static

Today, an old friend suddenly asked me why two seals are used for piston rod seals. Isn’t one seal enough? Although it seems like a

Glyd rings and step seals are the most common types of hydraulic cylinder seals. Let’s take a look at their installation methods and installation precautions.

Sealing solutions play a vital role in maintaining the efficiency and safety of various mechanical equipment. The choice between dynamic and static seals can significantly

Seals hold the hydraulic fluid or gas inside the hydraulic cylinder seals and piston system of hydraulic cylinders.

A liquid can take on the shape of its container, but can only fill the volume it can occupy. In a hydraulic system, fluid

There are some significant distinctions between hydraulic and pneumatic seals, two types of sealing devices that are utilized in various systems.

Spring-energized seals are widely used in various mechanical equipment due to their excellent sealing properties. Spring-energized seals play an important role in automobiles, ships, aerospace,

What is a spring energised seal? A spring-energized seal is a high-precision sealing element consisting of a sealing ring made of a high-performance polymer, PTFE,

Hydraulic technology is a control technology based on liquid pressure transmission. It is widely used in industry, agriculture, aviation, aerospace, energy, transportation, and other fields.