Floating Seal‘s Advantages VS Disadvantages

There are many advantages of floating oil seals. This article will help you to understand the main advantages and disadvantages to help you better apply floating oil seals.

There are many advantages of floating oil seals. This article will help you to understand the main advantages and disadvantages to help you better apply floating oil seals.

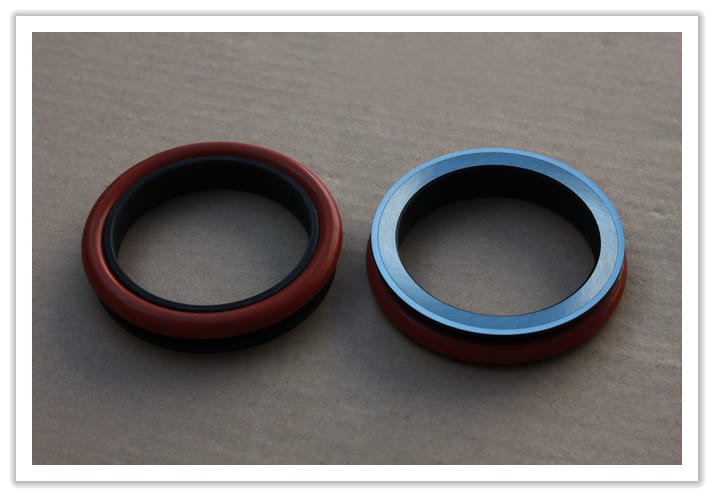

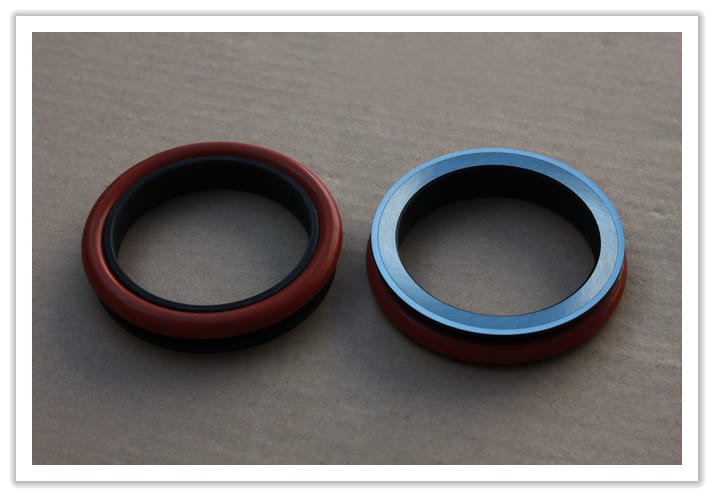

Floating seals (also called seal groups) were born in the late 1950s and were first used to replace rubber oil seals on bulldozer chassis.

We all know that hydraulic transmission uses pressurized liquid to achieve power transmission through changes in sealing volume.

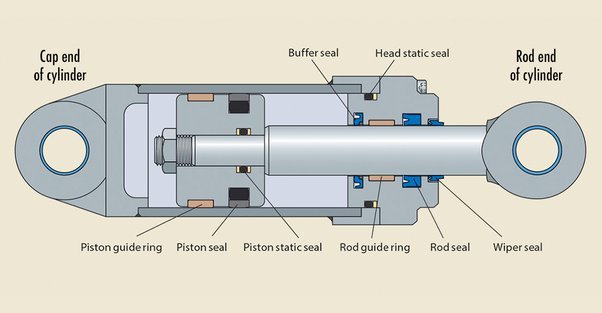

Cylinder seal kits usually consist of multiple sealing components, including O-rings, sealing rings, piston rod seals, piston seals, etc.

There are some significant distinctions between hydraulic and pneumatic seals, two types of sealing devices that are utilized in various systems.

Seals hold the hydraulic fluid or gas inside the hydraulic cylinder seals and piston system of hydraulic cylinders.

The hydraulic cylinder seal is installed on the shaft of the hydraulic pump and hydraulic motor.

Installing hydraulic cylinder seals is very important;

Seals for hydraulic cylinders are essential parts that keep fluid from leaking and allow the hydraulic system to work properly

We should pay attention to the piston seal on the hydraulic cylinder. If its sealing performance is not good, it will not only affect the

he O-ring is a rubber seal with a prototype cross-section.

Nitrile rubber and FKM are both very commonly used sealing materials, as elastomers they have their own unique properties and applications.